How Many Fiber Connector Types Do You Know?

- lan cable

- 29 Oct, 2021

Fiber optic cable connector that comes in various configurations and types is considered as an important component for the fiber optic cable. Multiple types have been launched on the market by various manufacturers. Generally speaking, fiber connectors can be categorized according to different standards like the popularity, the transmission method, the transmission media, the boot length, the polishing type and the termination way, etc. Follow this article to classify fiber connector types.

Utilization: Common and Uncommon Optic Fiber Connectors

No matter what the fiber connector types are, they have the same function and similar basic components—ferrule, connector body, cable, and coupling device. However, due to the performance and characteristics of these types, the utilization of them varies.

LC Connector

A Lucent Connector (LC), as one SFF (small form factor) connector, possesses a 1.25 mm ferrule. The small footprint design gives these connectors huge popularity in datacoms and makes them more ideal for high-density applications. Many tend to move to high-efficiency cabling with LC fiber connectors nowadays. LC connector is considered the most commonly-used connector at present.

SC Connector

SC fiber connector was the first connector chosen for the TIA-568 standard and is a snap-in connector that latches with a simple push-pull motion. "SC" stands for "Square Connector" due to the "square-shaped" connector body. It adopts a 2.5mm ferrule, which is twice the size of the previous LC connector. SC fiber connector is ideally suited for datacoms and telecom applications including point to point and passive optical networking. Due to its excellent performance, fiber optic SC connector remains the second most common connector for polarization maintaining applications.

MTP/MPO Fiber Connector

Unlike the previous two, the MTP/MPO fiber connector is a multi-fiber connector and larger than other connectors, which combines fibers from 12 to 24 fibers in a single rectangular ferrule. It's often used in 40G and 100G high-bandwidth optical parallel connections. The MTP/MPO fiber connectors are complicated due to the key-up and key-down, male and female issues.

ST Connector

ST (Straight Tip) fiber connector was created and licensed by AT&T shortly after the arrival of the FC type. The ST connector holds the fiber with a ceramic, spring-loaded 2.5mm ferrule that stays in place with a half-twist bayonet mount. They are usually used in both long and short distance applications such as campuses and building multimode fiber applications, corporate network environments, as well as military applications.

FC Connector

"FC" refers to the Ferrule Connector. FC fiber connector was the first optical fiber connector to use a ceramic ferrule. Unlike the plastic-bodied SC and LC connector, it utilizes a round screw-type fitment made from nickel-plated or stainless steel. The FC connector end face relies on an alignment key for correct insertion and is then tightened into the adaptor/jack using a threaded collet. Despite the additional complexity both in manufacturing and installation, the FC connectors still provide the choice in precision instruments such as OTDRs, as well as the choice for single mode fiber. It was initially intended for datacoms and telecoms applications but was used less since the introduction of the SC and LC. The usage of both ST and FC connectors have declined in recent years.

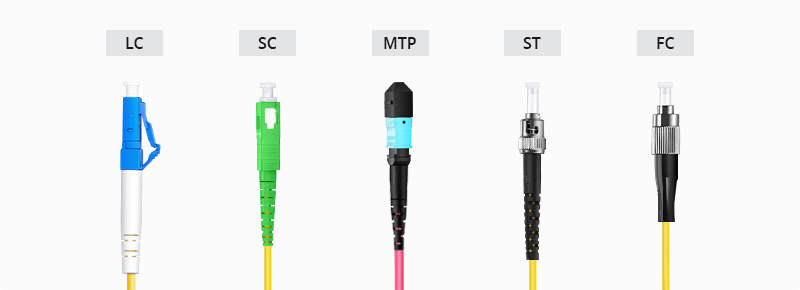

The abovementioned five connectors are the most commonly used ones, which are introduced based on their popularities from wide to usual. The figure below shows the different connector style:

The following four connector types are some old models that seldom used in today's optical transmission deployments:

MT-RJ Connector

A duplex connector uses pins for alignment and has male and female versions. Constructed with plastic housing and provide for accurate alignment via their metal guide pins and plastic ferrules.

MU Connector

Like a miniature SC with a 1.25mm ferrule. Featuring a simple push-pull design and compact miniature body, the MU connector is used for compact multiple optical connectors and a self-retentive mechanism for backplane applications.

DIN Connector

The DIN connector is round with pins arranged in a circular pattern. It encompasses several types of cables that plug into an interface to connect devices. Typically, a full-sized DIN connector has three to 14 pins with a diameter of 13.2 millimeters. It is applied for PC keyboards, MIDI instruments, and other specialized equipment.

E2000 Connector

The E2000 Connector is a push-pull coupling mechanism with an automatic metal shutter in the connector as dust and laser beam protection. One-piece design for easy and quick termination, used for high safety and high power applications.

Fiber Count: Simplex vs Duplex Fiber Connectors

A simplex connection means signals are sent in one direction—a signal is transmitted through two simplex connectors and a simplex fiber cable from device A to device B, which cannot return from device B to device A via the same route. Contrariwise, the revised transmission can be achieved through duplex connectors and duplex fiber cable, which is called a duplex connection. In addition, a simplex fiber connector is often connected with one strand of glass or plastic fiber, while the duplex fiber connector needs to connect with two strands of fibers.

Fiber Mode: Single Mode vs Multimode Fiber Connectors

Single mode fiber allows only one light mode to pass through at a time, while multimode fiber can propagate multiple modes at a time. Diversity has an impact on single mode fiber connectors and multimode fiber connectors on account of the combination with the corresponding type of optical fibers. However, with technologies getting advanced, fiber connectors like SC, LC, and FC, provided by fiber optic connector factories are compatible with single mode and multimode fiber cables.

Boot Length: Standard Boot vs Short Boot Connectors

As for the boot length, there are standard boot structure and short boot structure. A standard boot can protect the cable and the connector from being damaged, wires being dislodged from the connector body, etc. While a short boot has the same function, it is distinguished by a shorter boot structure. For places where there is limited space for connector, short boot cable can be the ideal choice. The short boot structure design can make the cable easily pass through the narrow space without sacrificing performance, making the installation and maintenance of the fiber optic cables more efficient.

Polishment: APC/PC/UPC Fiber Optic Connectors

According to the polishing type, optical fiber cable connectors can be divided into three types: PC, UPC, and APC connectors. The color code provides a convenient method to identify these three types of connectors: PC's color code is black, the color code for the APC fiber connector is green, and the UPC's connector is blue. The structure and the performance of the three fiber optic connectors also vary, which reflects on the values of insertion loss and return loss. Among them, APC tends to become the preferred polishing type.

Termination: Field-terminated vs Pre-terminated Fiber Connectors

Field termination, as its name implies, is to terminate the end of the fiber in the field. The procedure includes strip the cable, prep the epoxy, apply the connector, polish, inspect and test for the connection, requiring not only a large number of tools but also the skilled technicians to conduct the termination.

Factory termination, also called factory pre-termination, refers to cables and fibers terminated with a connector in the factory. The pre-terminated cables come in pre-measured lengths with the fiber optic connectors already installed with factory-level precision and quality assurance. Reducing the cumbersome process and tools, factory pre-terminated solutions are easier to install and require less technical skills.

| Fibers with Field Terminated Connectors | Fibers with Factory Terminated Connectors | |

| PROS | Cable Length Flexibility & Precision Easy Cable Routing Standard Procedure |

Factory Polish Quality Minimum Possible Insertion Loss Always Passes Testing |

| CONS | Time Consuming Requires a Kit Quality Depends on Skill and Components Consumes Materials Can Fail Testing and Must be Redone |

Must-Know Lengths Exactly Can be Too Bulky for Cable Tracks |